When I first got into RC cars, one of the most demanding components to maintain was the speed controller. Back then, mechanical speed controllers (MSCs) were the standard. They were simple, generally reliable, and got the job done, but they also had their fair share of quirks and limitations. Keeping the contacts clean and free of dirt so the arm could move smoothly across them was a constant challenge. Ultimately, I found that a strategically placed balloon was my best defense against grime. As the hobby evolved, so did the technology, and the introduction of electronic speed controllers (ESCs) marked a major turning point for RC enthusiasts everywhere.

The Era of Mechanical Speed Controllers

Mechanical speed controllers were the go-to technology in the early days of RC vehicles, including during my time with the Grasshopper and Hotshot. These controllers were relatively simple devices, consisting of a series of resistors and a wiper arm that physically moved to different positions to adjust the speed of the motor. The wiper arm was controlled by a servo, which was linked to the throttle on the transmitter. However, one of the critical aspects of these systems was managing the heat generated by the resistors. As the wiper arm adjusted the motor speed, it applied varying levels of resistance, which in turn produced significant heat. To prevent damage and ensure the controller’s reliability, heat sinks were essential for dissipating this excess heat. Without a proper heat sink, the resistors could overheat, leading to performance issues and potential failure. This added another layer of maintenance and complexity to using MSCs, making the eventual shift to electronic speed controllers (ESCs) a welcome advancement.

Pros of MSCs:

- Simplicity: The mechanical nature of these controllers made them easy to understand and repair. If something went wrong, it was usually a matter of replacing or adjusting a component.

- Cost: MSCs were relatively inexpensive, making them accessible to a wide range of hobbyists.

Cons of MSCs:

- Wear and Tear: Since MSCs relied on physical contact between the wiper arm and the resistors, they were prone to wear over time. This wear could lead to inconsistent performance and the need for frequent maintenance.

- Heat: The resistors in MSCs generated a lot of heat, especially at low speeds where the excess energy had to be dissipated. This not only reduced efficiency but also posed a risk of overheating.

- Limited Precision: The step-by-step nature of MSCs meant that speed control was less precise compared to what would come later with ESCs.

The Shift to Electronic Speed Controllers

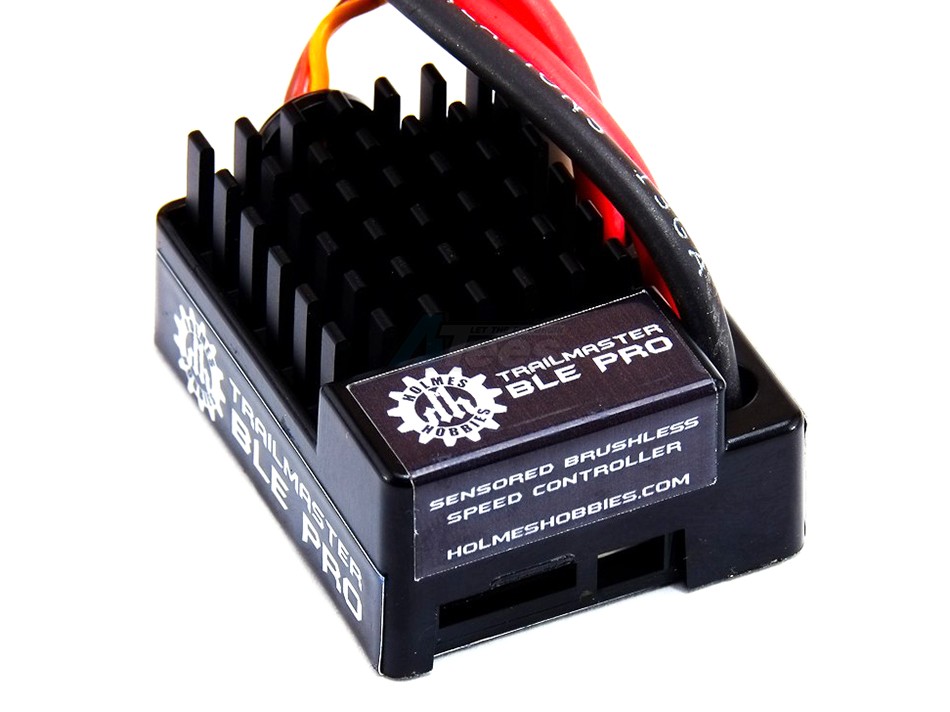

The introduction of electronic speed controllers (ESCs) in the late 1980s and early 1990s was a game-changer for the RC hobby. ESCs replaced the mechanical parts of MSCs with solid-state electronics, eliminating many of the issues that plagued their mechanical counterparts.

How ESCs Work: ESCs use transistors to control the amount of power sent to the motor, adjusting speed smoothly and efficiently. Instead of moving parts, ESCs rely on pulse-width modulation (PWM) to control motor speed. This method not only provides more precise control but also significantly reduces the amount of energy lost as heat.

Advantages of ESCs:

- Precision: ESCs offer infinitely variable control over motor speed, allowing for smoother acceleration and deceleration. This precision made RC cars more responsive and easier to handle, especially in competitive environments.

- Efficiency: Without the need for resistors, ESCs are much more efficient, reducing the heat generated during operation and extending battery life.

- Durability: The lack of moving parts in ESCs means less wear and tear, leading to longer-lasting components with less need for maintenance.

- Programmability: Many modern ESCs are programmable, allowing users to customize settings such as throttle response, braking force, and even motor timing to suit their specific needs and driving style.

My Experience Transitioning to ESCs

The first time I upgraded from an MSC to an ESC was in 2011. After having been away from the hobby for just over 20 years, I finally pulled my original Grasshopper and Hotshot out of storage. Making that upgrade marked a pivotal moment in my return to RCs, transforming the driving experience in ways I hadn’t imagined. But that’s a story for another post—stay tuned for more about my journey back into the world of RC after two decades away.

The Impact on the Hobby

The Impact on the Hobby

The widespread adoption of ESCs revolutionized the RC hobby, making RC cars more reliable, efficient, and easier to drive. This shift opened the door for more advanced and competitive models, as ESCs became the new standard. They also paved the way for further innovations, such as brushless motors and more sophisticated radio systems.

Today, it’s hard to imagine the RC world without ESCs. They’ve become so integral to the hobby that even entry-level models now come equipped with them. For those of us who started with mechanical speed controllers, the transition to ESCs was a revelation—one that significantly enhanced our enjoyment and, at times, the complexity of the hobby.

Looking Forward

As technology continues to advance, so too does the development of ESCs. Modern ESCs now offer features like telemetry, which allows drivers to monitor their car’s performance in real-time, and regenerative braking, which helps to extend battery life even further. The future of RC is undoubtedly bright, and it’s exciting to think about what innovations might be just around the corner.

But no matter how advanced the technology becomes, I’ll always remember the thrill of that first upgrade—the day I swapped out my mechanical speed controller for an electronic one and realized just how far this hobby could go.

— Coby R

Leave a comment